Has your company been on a roll? Are you happy with your results from last year? I have to admit the reflection in my mirror shows plenty of room for improvement. There is always more to be done. Making it happen is the challenge. It’s more than a matter of prioritization. The place to start is with my mindset. Business owners know this instinctively or have learned it along the rocky road to entrepreneurship. New results in a new year require new thinking. Here’s why.

By nature we are risk takers. A certain amount of risk can be profitable. Wealth managers refer to managed risk. However, people are also gamblers. Big difference! Let me illustrate with a grocery store example. Picture a parent with child(ren) at checkout. Child throws temper tantrum over something he or she wants. Parent (after scolding and “firm” threat) buys child the item of controversy. Child learns that sometimes Mom or Dad gives in and he or she gets the desired item. Child reasons “maybe this time my tantrum will pay out”.

Now picture another parent with children shopping an isle over. The line moves smoothly through checkout while children politely help parent, placing things on the conveyor. Child has previously learned that Mom or Dad will not give in; the odds are against at temper tantrum. Grandma behind them comments to her friend what “well behaved children” those are. Why the difference? It has to do with a different mindset — of both parent and child. The principle is:

We witness the results (poor behavior). However, the mindset is more subtle. It is easy to criticize the results but unless the way of thinking is (mindset) corrected we can expect more of the same results. We all have a certain amount of “gambler” within us, investment risk, business start-up risk, safety risk on the job site, or risk at the Black Jack table in Lost Wages, NV.

If, as a business leader I don’t like the results one of my employees produces, I have identified a symptom. Others, even my customers, may see and feel the symptom as well — not good. A root cause analysis would likely reveal a deeper issue to address — the thinking.

The key to getting the positive results hoped for in business and in life is to address not the result, not the action, but the thinking itself. The thinking is the root cause.

Psychologists tell us that mindset is comprised of many aspects (emotional, spiritual, physical, etc.). Allow me to delve into just one area: wrong thinking in the workplace, leading to wrong actions, and less-than desirable results in the workplace. Even more specifically, let us use the example of a worker in industry. Lest I lose some of you here, don’t allow your own thinking to tell you, “this article doesn’t apply to me”. Please continue.

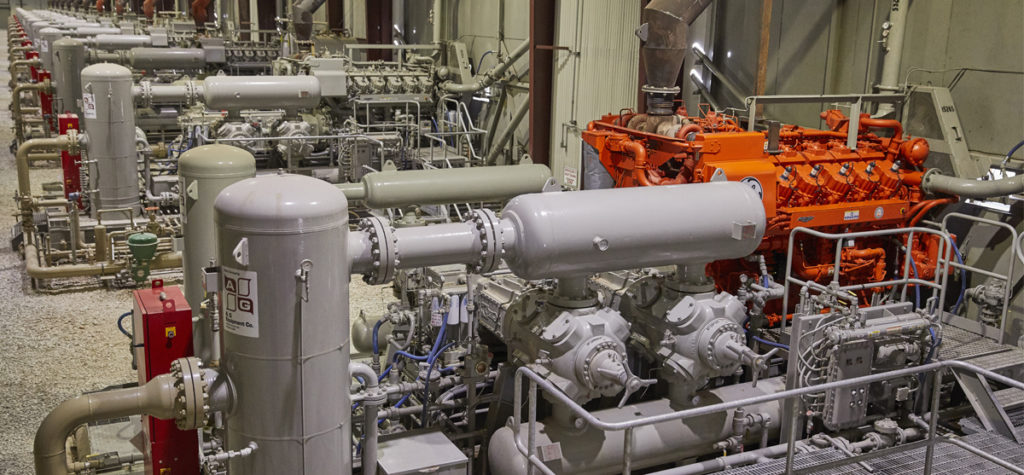

Here’s a real life illustration of a field worker and his company. Having received partial training, “Technician A” was recognized as the knowledgeable “engine guy”. He was tasked with completing a “startup” of a large natural gas engine/compressor package at We Mash Gas Compression Co. The desired result by day’s end was an operating unit producing full load and pushing gas down the pipeline. The company was shorthanded that day; the instrumentation and electrical (I&E ) guy, “Technician A”, was working on another site. Technician “B” was not familiar the engine’s electrical control system — work that was normally done by an I&E tech. Upon powering the site, Technician “B” realized the control system did not seem to be ON. After minor troubleshooting, he assumed the problem had to be “the box”. He proceeded to swap the main electrical control box from a sister engine of the same model on site. Upon powering the system a second time and seeing the same results, he reasoned that both electrical boxes were “bad” from the factory. (Yes, this is a true story, and…it gets worse.) By the time help arrived the next day, the electrical boxes from all three engine units had been fried by trial and error, “gambling”. Beside the cost of down time and lost production, equipment damage easy equaled a few month’s wages.

I won’t go down the rabbit hole why this situation occurred or how it should have or could have been prevented. (When I see you in class we can talk about that.) It became painfully obvious by the next day that Technician B’s thinking played a major role in the disaster. His thinking went something like: “These are electrical boxes. Electrical boxes are prone to problems. Each box was defective from the factory.”

The gambler mindset yielded “gambler results”. We can view hundreds of video clips online of “dumb” accidents, usually posted by someone involved with safety training. I’ll make an educated guess that safety trainers know the gambler mindset.

Would technical training have prevented these results? I can’t guarantee that. However, good technical training would have stressed that the entire electrical control system would have been operating when the engines were factory tested. Attendees would have been instructed about the requirements for site power (clue #1). A week of technical training on the subject could likely have saved this company tens of thousands of dollars in down time, repair, and lost revenue.

The need to have sufficient numbers of trained workers on site becomes obvious considering the scenario above. Thomasnet.com recently reported that “on average, companies are losing $800,000 annually due to less business and productivity as a direct result of the skills gap”.

Lots of generic training is available online. However, in this case specific, product knowledge was needed. If there is no change in thinking, there will be little chance of improved future results (performance).

Are you a technical training decision maker? Are you gambling with providing training for your people?

After serving the Oil & Gas industry for over three decades and training hundreds of technicians world-wide, I saw a crying need for product-specific training in the marketplace. SnackLearning was born out of a desire to solve that problem.

Good training includes real life examples and analogies to educate and influence behavior. Good training starts with why. When people know “why” (or why not) their thinking is influenced. Change doesn’t happen over night, but good training must always address “why”. Ultimately you want employees who can apply the knowledge they have learned. Informed thinking leads to better choices (actions) and better outcomes (results).

Improved thinking = improved actions = positive results.

The time to think seriously, about taking training seriously, is now! I invite you to join me in a conversation, and…

ask me in class to share the rest of the control system nightmare story, how it ended, and the amazing root cause for some onsite problems — all preventable with training.